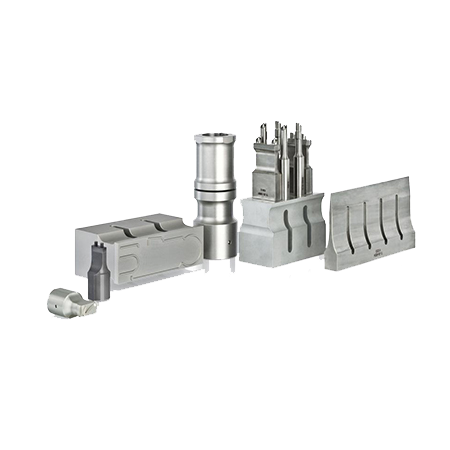

Ultrasonic mold tooling

1. What is an ultrasonic mold: Ultrasonic molds, also called ultrasonic horns, are the general term for all ultrasonic transmitting ends and are an indispensable part of ultrasonic welding equipment. Its function is to couple the ultrasonic waves generated by the transducer into the object being processed. Because it is to transmit ultrasonic waves, the welding head must work in a resonant state, that is, its natural resonant frequency should match the transducer. Secondly, the amplitude should be uniform, and the shape of the end face of the welding head should be adapted to the shape of the workpiece to be welded. Second, the ultrasonic welding head material: titanium alloy, magnesium aluminum alloy, powder metallurgy steel, etc. Third, the customization of ultrasonic mold:

Guosheng ultrasonic welding transducer has the following characteristics:

1. Low resonance impedance;

2. High Q value of machinery;

3. High efficiency of electro-acoustic conversion;

4. Low calorific value;

5. Large amplitude and high velocity.

Notes for transducer installation:

1. Select suitable materials and adjust hardness technology to process and produce horn and working head.

2. Attention should be paid to frequency matching when installing horn or working head, and sound guide glue should be applied at the joint.

3. Use acetone and other solvents to clean the jointed surface during installation.

4. Establish the impedance control technology of the joining process to reduce the joining impedance of the oscillator and improve the electro-acoustic conversion efficiency of the oscillator.

5. Attention should be paid to improving the insulation measures after the installation of oscillator electrodes.