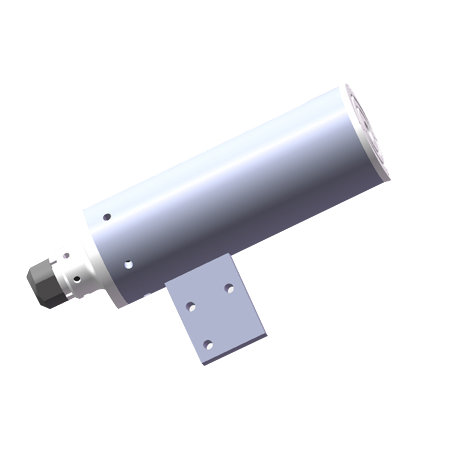

Ultrasonic finishing equipment

1. Introduction The ultrasonic surface surface processing equipment can be used instead of the original ordinary tool to improve the surface finish of the workpiece to be improved by more than 3 grades (roughness Ra value of 0.1 or less), comparable to the grinding and plating functions, and the surface microhardness is improved by 20 Above %, and reducing the friction coefficient of the metal surface improves the surface wear resistance and corrosion resistance of the workpiece. This product is suitable for steel, iron, copper, aluminum stainless steel and other materials with hardness less than 55HRC. It is widely used in machinery, automobile, military, bridge, aerospace and other fields (such as motor shaft, piston rod, hydraulic cylinder, brake pad, etc.). component). 2. Super

The surface finish of the machined workpiece can be improved by replacing the conventional cutting tool with the ultrasonic metal surface processing equipment. The product is suitable for steel, iron, copper, aluminum and stainless steel.

Treatment effect of ultrasonic metal surface processing equipment:

1. The surface roughness of the treated metal is lower than that before finishing.

2. The surface hardness of the treated workpiece is increased.

3. The corrosion resistance of the treated metal surface is several times higher than that of the un-polished metal surface.

4. The stress field of the treated metal surface changes, which is conducive to the improvement of the comprehensive performance of the metal workpiece.

5. The fatigue resistance of the treated metal surface increases.

6. After treatment, the micro-defects of metal surface can be eliminated and the initial damage of workpiece can be reduced.

7. The friction resistance of the treated metal surface decreases.

Scope of application of ultrasonic metal surface processing equipment:

It is used to manufacture many precision parts such as mechanical axles, piston rods, hydraulic cylinders, brake pads, and many of them are used in the following industries: aviation, automobiles, bridges, mechanical parts processing, oil pipelines, railways, ships and other industries. Specifically, there are the following aspects:

The outer surface of rod and tube is smooth.

1. The surface of the plane is smooth.

2. Inner hole surface is smooth.

3. The surface of thin-walled sleeve parts is smooth.

4. Surface finish of serrated workpiece.

5. The working surface of gear workpiece is smooth.

6. The surface of bearing inner and outer rings is smooth.

7. Excessive surface smoothing of arc.