Composition and Structure of Ultrasou...

Ultrasonic plastic welding machine consists of ult

Basic Structure and Characteristics o...

Ultrasonic cutting machine is a device that uses w

Installation of ultrasonic metal spot...

one. Structure and principle of ultrasonic metal s

Ultrasonic plastic welding machine in...

Mold calibration procedure: In order to achieve me

Ten Common Senses of Ultrasound Weldi...

The ultrasonic welding machine is a High-tech to m

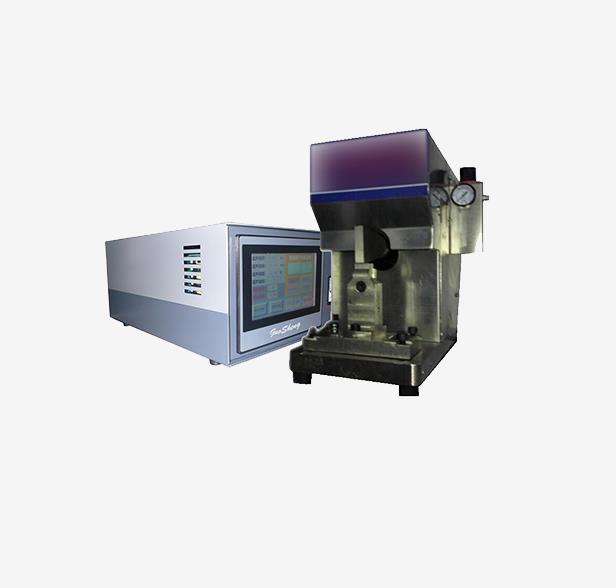

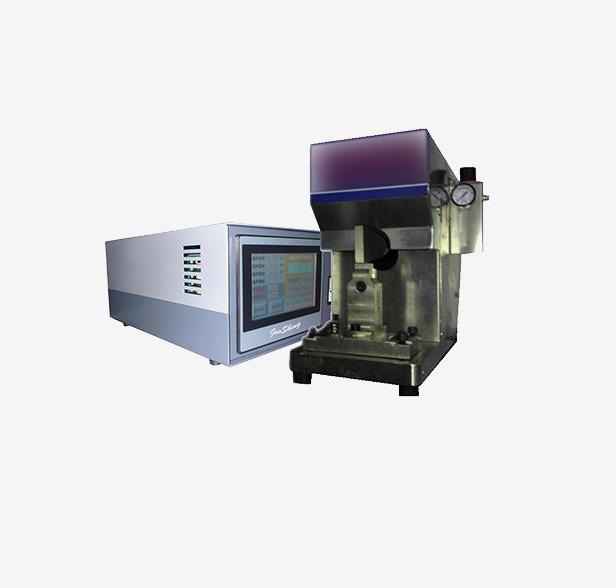

Brief description of ultrasonic metal...

Simplified ultrasonic metal spot welding machine a

Further Understanding of Ultrasound P...

Learn more about ultrasonic plastic welding machin