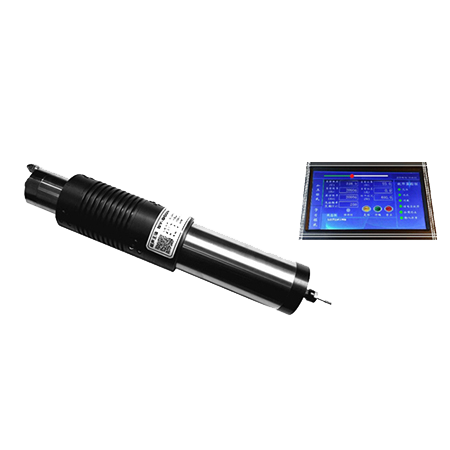

Ultrasonic rotary processing equipment

With the continuous innovation of materials science, today's high-tech weapons manufacturing, spacecraft, ultra-power chip substrates, medical devices, communications and other fields, the use of new composite materials, such as: carbon / carbon composite materials, aluminum-based silicon carbide, carbon Ceramics, single crystal metals, alloys and hard and brittle materials with a Mohs hardness of more than 4; conventional processing methods are inefficient and difficult to meet the process requirements, resulting in high manufacturing costs. This product accommodates a number of technologies, such as mechanical electroacoustic conversion, non-contact transmission and other properties. Mainly used in precision CNC machine tools and CNC machining centers; processing hard and brittle materials and difficult to process metal materials.

Rotary ultrasonic compound processing system, that is to say, compound ultrasonic vibration on the cutting tool and rotate the workpiece. It is different from the previous ultrasonic abrasive fluid processing. Its principle is to apply ultrasonic vibration on the original machined tool. Compared with conventional mechanical processing, ultrasonic composite processing technology has the following characteristics:

1. Cutting resistance is greatly reduced. The reason is that ultrasonic vibration breaks the machined surface of the workpiece into tiny marks, and the tool head can easily cut off the material. The reduction of cutting force not only improves the production efficiency, but also reduces the cutting heat due to the intermittent contact of high frequency, makes the tool head not easy to lock and twist, reduces the tool wear and improves the service life of the tool. The mechanical force applied to the workpiece decreases, which is especially suitable for processing hard and brittle materials which are easy to break and viscous metal materials.

2. Good chip removal effect. Under the action of ultrasonic wave, coolant is sprayed onto the surface of workpiece to form cavitation effect, which accelerates the flow rate of liquid equivalent to ultrasonic cleaning on the surface of workpiece, improves the chips removal and accelerates cooling effect of coolant. Chips are uniform fine powder or chips, which are easily discharged, and reduces the scratches and cracks in the inner hole. The appearance of grain greatly improves the processing smoothness.

3. Rigidity of tool head is improved. Ultrasound makes the tool head rigid, which makes it difficult to bend, thus improving the accuracy, concentricity and cylindricity of the cavity and hole. It is suitable for processing optical glass, semiconductor (silicon, germanium), ceramics and so on. There are no microcracks in the cavity.

4. Save (energy) and benefit is good. Because of the ultrasonic interference, the tool generates 20,000-45,000 times of ultrasonic vibration per second, the tool life is improved, and the common spindle can meet the processing requirements. Its spindle speed can be selected at 5000 rpm/min-15,000 rpm, and it does not need to be equipped with ultra-high speed motorized spindle (such as 60,000-100,000 rpm spindle), rotational speed and cutting resistance. The reduction of force greatly saves the power consumption and prolongs the service life of the spindle, thus reducing the cost.

application area

Mainly used in precision CNC machine tools and CNC machining centers; Processing hard and brittle materials and hard-to-process metals, in milling, cutting, drilling micro-holes, grinding, especially processing aluminum-based silicon carbide, carbon/carbon composites, ceramics, sapphire, YAG yttrium aluminium garnet, artificial crystal, jadeite, optical glass, semiconductor materials (silicon). Germanium, ferrite, cemented carbide, permanent magnet material, stainless steel, superalloy, etc., have excellent performance.