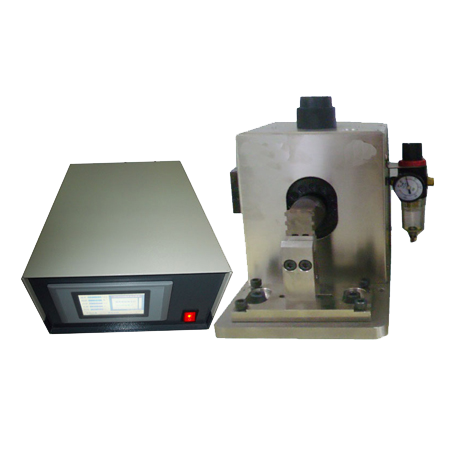

Ultrasonic metal spot welder

Ultrasonic metal spot welding machine ultrasonic welding is a fast, clean and economical technology, widely used in various automation industries. The ultrasonic metal welding process is a process between cold press welding and friction welding that utilizes high density energy generated by high frequency mechanical vibration. The mechanical vibration of the welding head of the ultrasonic metal welding is parallel to the surface of the workpiece. During welding, the static pressure acts perpendicularly on the welding surface through the welding head, and at the same time superimposes the shearing force of the high-frequency vibration. When the shearing force exceeds the elastic limit of the material, the part of the contact surface of the workpiece begins to slip. This shearing force In the welding process, the frequency is tens of thousands of times per second.

Ultrasonic wave metal spot welder

Ultrasound metal spot welding machine is suitable for welding the same or different metal parts with less energy. The high frequency electric energy is converted into mechanical vibration energy by transducer to act on the workpiece of ultrasonic metal spot welding machine, which produces high frequency friction between the two workpieces'surfaces until the two workpieces' surfaces are heated and fused together. Under appropriate pressure, the metal surface molecules are penetrated into each other through cold grinding and horizontal movement to achieve welding. Objective Equipment. It is an ideal equipment for single-point, multi-point, square, strip, single-layer, multi-layer and composite welding of fine and thin materials such as aluminum, nickel, copper and silver.

Equipment characteristics

1. Double CPU numerical control system.

2. Frequency synthesis technology, automatic frequency tracking, replacing the adapted die without manual tuning, adaptive working environment.

3. Automatic Frequency Modulation and Storage (AT/M): Start-up automatically detects the frequency of the welding head, and automatically stores the frequency of the welding head after each welding.

4. Welding amplitude can be adjusted.

5. Servo voltage stabilization control system with automatic amplitude compensation can overcome the bad welding caused by unstable power supply.

6. Built-in frequency offset, overload protection system.

7. Built-in fault self-diagnosis device.

8. Alloy steel welded joint has long service time and good wear resistance.

Equipment parameters

Specific parameters are determined by customization requirements of customer product selection. Different equipment types have different parameters. Examples of parameter configuration are as follows:

1. Ultrasound frequency: 15KHZ, 18KHZ, 20KHZ, 25KHZ, 28KHZ, 30KHZ, 35KHZ, 40KHZ, 43KHZ, 56KHZ, 60KHZ and other models.

2. Ultrasound power: 300W, 600W, 800W, 1000W, 1200W, 1500W, 2000W, 2200W, 2600W, 3000W, 3200W, 3500W, 4200W, 5000W, 6000W, 7000W, 8000W, 10KW, 15KW, 20KW, etc.

Characteristics of Ultrasound Metal Welding

1. Welding materials do not melt and are not fragile.

2. After welding, it has good conductivity, good thermal conductivity and low resistance coefficient.

3. Low requirement for welded metal surface, oxidation or electroplating can be welded.

4. The welding time is short and no flux, gas or solder is needed.

5. It is easy to realize the connection and automatic control between different metals.

6. No spark welding, fast speed.

The application fields of ultrasonic spot welding machine involve hardware, battery, electronics, automobile, motor, electrical appliances and other industries, including: welding of aluminium strip and aluminium cover, welding of nickel strip and copper foil (multi-point), welding of aluminium strip and aluminium foil (strip), welding of aluminium strip and aluminium foil (multi-point), and welding of nickel with aluminium strip and aluminium foil (multi-point). Strip and aluminum strip, nickel strip and copper foil, nickel strip and copper foil multi-layer, aluminum strip and aluminum foil multi-layer, aluminum shell and aluminum-nickel composite strip welding, nickel strip and copper foil multi-layer, aluminum strip and aluminum foil multi-layer, copper tube sealing, automobile wiring harness, motor terminal welding.