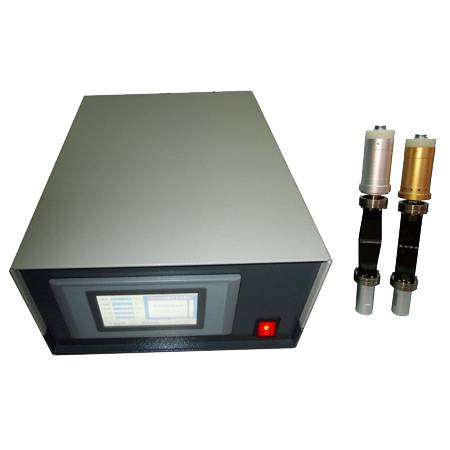

Ultrasonic film machine

Introduction of Guosheng Ultrasonic Film Making Machine: Guosheng Ultrasonic Film Making Machine is specially used for automatic filming machine. It is a full wave series product, suitable for winding positive electrode and negative electrode sheet of winding electric core. Our original tooth discharging technology On the basis of the traditional single row of teeth, the innovative use of double row of teeth, covering a large area, thereby reducing the number of times the automatic film machine needs to move multiple times in the large-capacity pole piece with large welding area, improve efficiency, increase Large contact area. High welding efficiency, low internal resistance, stability and consistency. The characteristics of Guosheng ultrasonic filming machine are as follows: 1. High reliability: Ultrasonic welding can pass high-precision penetration control and energy control.

Aiming at the matching use of automatic film maker, the ultrasonic film maker is a full-wave series product, which is suitable for the welding of positive and negative plates of coiled cores. Based on the traditional single row teeth of the ultrasonic film maker, the tooth arrangement technology designed by our company uses double row teeth, which covers a large area, thus reducing the welding surface of the automatic film maker. When the large volume pole piece needs to be moved many times, the efficiency is high and the contact area is large.

Equipment features:

1. Double CPU numerical control system.

2. Frequency synthesis technology, automatic frequency tracking, replacing the adapted die without manual tuning, adaptive working environment.

3. Automatic Frequency Modulation and Storage (AT/M): Start-up automatically detects the frequency of the welding head, and automatically stores the frequency of the welding head after each welding.

4. Welding amplitude can be adjusted.

5. Servo voltage stabilization control system with automatic amplitude compensation can overcome the bad welding caused by unstable power supply.

6. Built-in frequency offset, overload protection system.

7. Built-in fault self-diagnosis device.

8. Alloy steel welded joint has long service time and good wear resistance.

The specific parameters of equipment are determined by the customization requirements of customer's product selection. The parameters of different equipment types are different. Examples of parameter configuration are as follows:

1. Ultrasound frequency: 35KHZ, 40KHZ and other models.

2. Ultrasound power: 600W, 800W, 1000W, 1200W and other models.