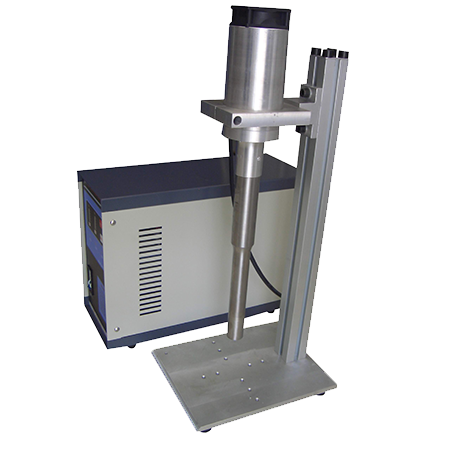

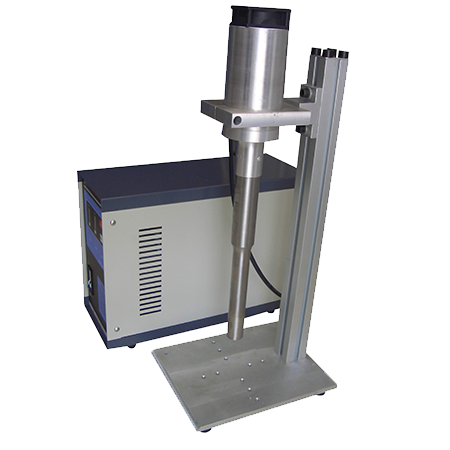

Ultrasonic emulsification equipment

1. Introduction Ultrasonic emulsification refers to the mixing of two (or more) non-phase solutions under the action of ultrasonic energy to form a dispersion system in which one liquid is evenly distributed in another liquid to form an emulsion. Process 2. Principle The physical mechanism of pulverizing insoluble solids (or liquids) is considered to be ultrasonic cavitation. Ultrasonic cavitation effect means that under the action of strong ultrasonic waves, a large number of bubbles will be generated in the liquid. The small bubbles will gradually grow and increase with the ultrasonic vibration, then suddenly burst and split, and the bubbles after the split will continue to grow and burst. . When these small bubbles collapse rapidly, high temperatures are generated in the bubbles.

Ultrasound emulsification refers to the process of mixing two (or more) non-aqueous solvents to form a dispersed system under the action of ultrasonic energy. One of the liquids is evenly distributed in another liquid to form an emulsion. Ultrasound cavitation effect refers to the large amount of gas generated in the liquid under the action of strong ultrasound. Bubbles, small bubbles will gradually grow and grow with the ultrasonic vibration, then suddenly burst and split, and the split bubbles will continue to grow and burst. When these small bubbles break up, high temperature and high pressure are produced in the bubbles, and strong local shock waves are produced in the liquid near the bubbles because the liquid around the bubbles rushes into the bubbles at high speed, and local high temperature and high pressure are also formed, which results in the smashing and emulsification of ultrasound.

Equipment characteristics

1. the average droplet size of emulsion formed by ultrasonic emulsification is small.

2. High Concentration of Ultrasound Milk

The emulsion formed by 3. is stable and can produce stable emulsion without or with less emulsifier.

4., the type of emulsion can be controlled.

5. The power required to produce emulsified slag by ultrasonic emulsification is small.

application area

In the pharmaceutical industry and daily necessities industry, ultrasound emulsification is often used to manufacture various emulsion products, such as emulsion drugs, cosmetics and leather shoes. The emulsified combustibles of oil (gasoline, diesel, etc.) and water or pulverized coal can also be produced by ultrasonic emulsification to improve the combustion value of unit fuel.

Ultrasound emulsification has been applied in many fields, and plays its role in many fields. Phacoemulsification is a technology used in food processing. Such as soft drinks, tomato sauce, mayonnaise, jam, artificial milk, baby food, chocolate, salad oil, oil, sugar and water and other mixed foods used in the food industry.